Internal Combustion Engine Cycles - Otto and Diesel

- rameez badhurshah

- Sep 24, 2021

- 6 min read

A century back, the transport heavily relied on carts tied to animals. And then, the world saw motorbikes, cars, ships and aeroplanes. The vehicles over the years have had large scale transformations in their shapes, weights, structures and performance. However, the engines still work on fundamental principles and cycles given back in 1861 and 1895. So, let's chip in to check how these cycles have survived the battle so long!

Table of Contents

Introduction

In the last post, we tried to understand the Carnot engine cycle. Ofcourse, this cycle was ideal and not practical. We have all heard about the petrol pumps or the gas stations, some of us might also be regularly visiting them. Most of these stations sell fuels such as petrol and diesel. As a learner to the subject, we know light motor vehicles like motorbikes, scooters and cars often fill their tanks with petrol and heavy vehicles like trucks, busses and to some extent, some SUV cars fill their tanks with diesel. Let's understand, why do we need different fuels for different vehicles and how do these engine cycles work. Also, why are these called internal combustion cycles? Again, we would be light on equations and try to understand the physics rather than the mathematics behind these cycles.

Classification of thermodynamic cycles

Based on the operating cycles, all the thermodynamic cycles can be classified broadly into two categories - power cycles and refrigeration cycles. The thermodynamic cycles which produce a power output are power cycles and the devices working on such cycles are often engines. While the systems working on producing a refrigeration effect are called the refrigeration cycle. The common devices working on refrigeration cycles are heat pumps, air conditioners and refrigerators.

On the basis of the phase of the working fluid, thermodynamic cycles can be either gas cycles in which the working fluid remains in a gaseous state or vapour cycles in which working fluid exists in vapour state for some part of the cycle and for another part it remains in the liquid phase.

Yet another classification could be based on the recirculation of working fluid. If the same working fluid at the end of one cycle is recirculated, the cycle is closed whereas if at the end of one cycle, if the working fluid is replaced, the cycle is an open cycle.

Classification of heat engines

Based on the supply of heat to the working liquid, heat engines could either be internal combustion engines or external combustion engines. In external combustion, heat supply takes place through external means like a nuclear reactor or a furnace. In internal combustion engines, the heat supply takes place within the system boundaries. Engines working on the Otto cycle and Diesel cycle are internal combustion engines.

Air Standard Assumptions

The gas power cycles in real have a complex mechanism. For example, during the exhaust cycle of the internal combustion engine, working fluid is released out of the engine, thus the thermodynamic cycle is not completed by the working fluid. Thus, to carry out the analysis of the gas power cycles, we put forward certain assumptions, which are more generally known as air-standard assumptions.

The air is used as a working fluid and assumed to continuously circulate in a closed loop. The air is assumed to behave as an ideal gas.

The processes are internally reversible.

We replace the combustion process with an external heat addition process

And the exhaust process is replaced as a heat rejection process. Post this process, the working fluid is assumed to return to its initial state.

Common nomenclature used in reciprocating engines

Top dead center (TDC) - The position of the piston in the cylinder when it forms the smallest volume. The minimum volume is also called clearance volume

Bottom dead center (BDC) - When the piston forms the largest volume in the cylinder. The maximum volume is also called displacement volume.

Stroke - When the piston completes its path from TDC to BDC or from BDC to TDC, the distance covered is called a stroke.

Bore - The maximum diameter of the piston is called the bore. A small tolerance is provided between the piston and cylinder

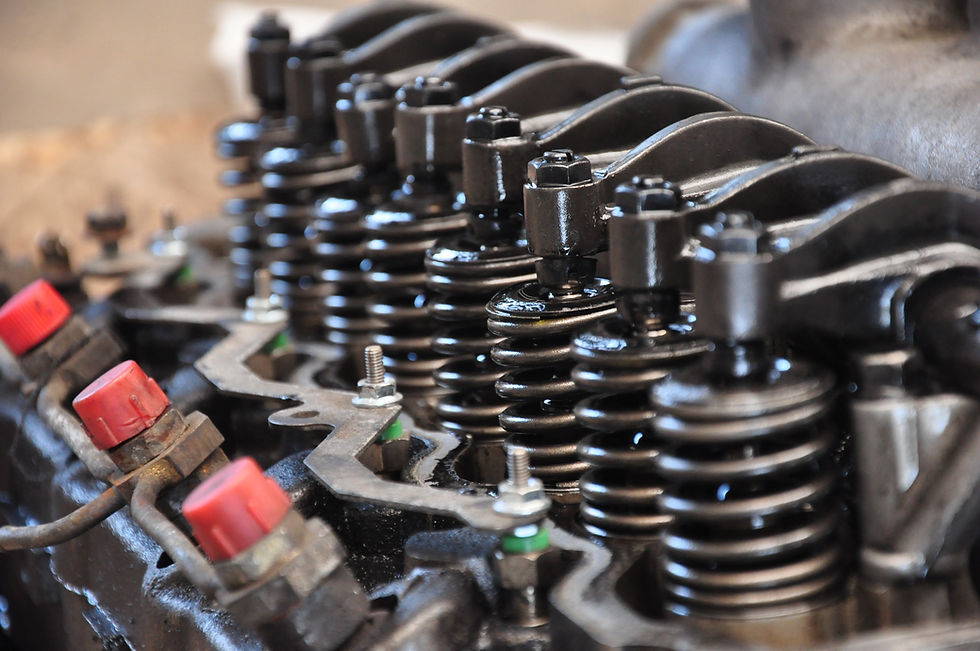

Intake valve - The entry path of the air or the air-fuel mixture into the cylinder

Exhaust valve - The exit path of the combustion products from the cylinder

Compression ratio - The ratio of maximum volume to the minimum volume

Mean effective pressure (MEP) - The pressure acting on the piston that would produce the same net work during an actual cycle. Usually, MEP is a measure that compares the performance parameters of equal-sized engines.

Otto Cycle

Otto cycle was first designed by Nikolaus Otto back in 1876. Otto cycle is more commonly used in four-stroke spark ignition reciprocating engines. Here, during the four strokes, that is when the piston from between TDC and BDC four times, the crankshaft connected to the piston completes two revolutions. We next discuss the ideal Otto cycle. The actual Otto cycle differs from the ideal cycle but for the sake of simplicity and understanding basic ideas, we restrict our discussion only to the ideal cycle. We have shown the ideal Otto cycle and the schematics that take place in the piston in the figures below.

The ideal Otto cycle consists of four processes described below

Process 1-2: The piston at the start of this process is at the lowest position (BDC). This process is called isentropic compression. The piston then starts moving upwards, thereby compressing the air-fuel mixture.

Process 2-3: At this process, heat addition at constant volume takes place. In the cylinder, the spark plug ignites the air-fuel mixture. This, in turn, increases the pressure and temperature in the cylinder

Process 3-4: This high pressure pushes the piston back to BDC, thereby isentropic expansion takes place. The crankshaft connected to the piston rod thus rotates and produces a net work. This stroke is thus called the power stroke.

Process 4-1: Heat release takes place in this process. The piston moves back to TDC from the BDC and the combustion products are released through the exhaust valve.

This completes the cycle, thus we see out of the four-stroke, only 1 stroke produces power. There also exists a two-stroke engine in which one is power stroke while the other is the compression stroke.

However, due to the incomplete combustion of products, two-stroke engines are generally less efficient than their four-stroke counterparts. The efficiency of the Otto engine is given by

where r is the compression ratio and k is the specific heat ratio

Diesel cycle

Diesel cycle is an ideal compression-ignition reciprocating engine. The major difference in combustion ignition as compared to that of spark ignition is that, here the during the compression stage, only air is compressed up to an autoignition temperature of the fuel and then fuel is sprayed/injected on this hot air. Thus, in compression ignition engines, only fuel injectors are needed. As only air is compressed, the compression ratios of compression ignition engines are comparatively higher than the spark-ignition engines. We next plot the typical P-v diagram for the Diesel engine and discuss the various processes involved.

The ideal Diesel cycle also consists of four processes. In fact, three of the process are exactly the same as the Otto cycle. The only difference is the process, wherein the heat addition takes place at constant pressure. The processes are presented as follows

Process 1-2: The piston starts from the lowest position (BDC) and moves upwards thus compressing the air. This process is called isentropic compression. It is to be noted that only air is compressed at this stage and hence the compression ratio obtained is much higher than that of the Otto cycle.

Process 2-3: At this process, heat addition at constant pressure takes place. In the cylinder, fuel is sprayed on the hot compressed air. The temperature in the cylinder increases.

Process 3-4: This force on the piston moves it back to BDC. This stage is called isentropic expansion. The crankshaft connected to the piston rod thus rotates and produces a net work. This stroke is thus called the power stroke.

Process 4-1: Heat release takes place in this process. The piston moves back to TDC from the BDC and the combustion products are released through the exhaust valve. Also to note here, the fuel used in Diesel engines is less refined as there is no problem of autoignition of the air-fuel mixture.

The efficiency of the Diesel engine is given by

where r is the compression ratio, rc is the cutoff ratio defined as the ratio of cylinder volumes after and before the combustion process and k is the specific heat capacity.

History

The design of the Otto cycle was first proposed by Frenchman Beau de Rochas as early as 1862. Nikolaus Otto worked on the idea of converting this cycle into a practical engine and he achieved this success in 1876. The Diesel engine cycle was proposed by Rudolph Diesel in the 1890s. Although these cycles may seem a century old in the implementation of engines, several changes and research have taken place over the years. For example, direct fuel injection, electronic controls as well as fuel constituents. These have helped improve the efficiency and the exhaust gas quality as well.

Summary

We classify the cycles and finally bottom it down to the engine cycles.

Next, we see the terminologies involved with the cylinder and piston of the engine

And finally, we understand two major cycles on which most of the automobiles work - Otto and Diesel engine cycle.

References

Cengel, Yunus A., Michael A. Boles, and Mehmet Kanoglu. Thermodynamics: an engineering approach. Vol. 5. New York: McGraw-hill, 2011.

Ganesan, V. Internal combustion engines. McGraw Hill Education (India) Pvt Ltd, 2012.

.png)

Comments